Component

-

Plate Die Series

PVC coating die adopts special channel of coat-hanger structure, adjustable upper die lip, perpendicular blocking bar, the thickness of production can be adjusted.

In pairs, special-purpose conveyor belts with different thicknesses and sizes can be produced. These kinds of products are widely used in mining, storage, transportation, and so on.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Sheet Die Series

Fast opening die series, the upper die lip with fine-tuning push-pull type, the flexible lower die lip can adjusting product thickness online without stopping, the Max adjusting range up to 5 mm, Equip with 45 ° blocking bar, it is suitable for produce PC, PS, PP, PE, PLA, single-layer or multi-layer plate.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Film Die Series

The film dies head adopts an extension V shape water-drop type flow channel, with the shunt technology and special triangle stabilize the structure. To composite layer and improve the precision of the extrusion process to eliminate ‘M’ shape and ‘W’ shape flow patterns effectively.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Screw&Barrel

Material: Alloy steel.

Application: heat and nitriding treatment.

Model: Screw and Barrel (single/twin).

Suitable plastic material: PP, PE, ABS, PS etc.

Effective length: 12000mm.

Bimetallic type: centrifugal casting.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

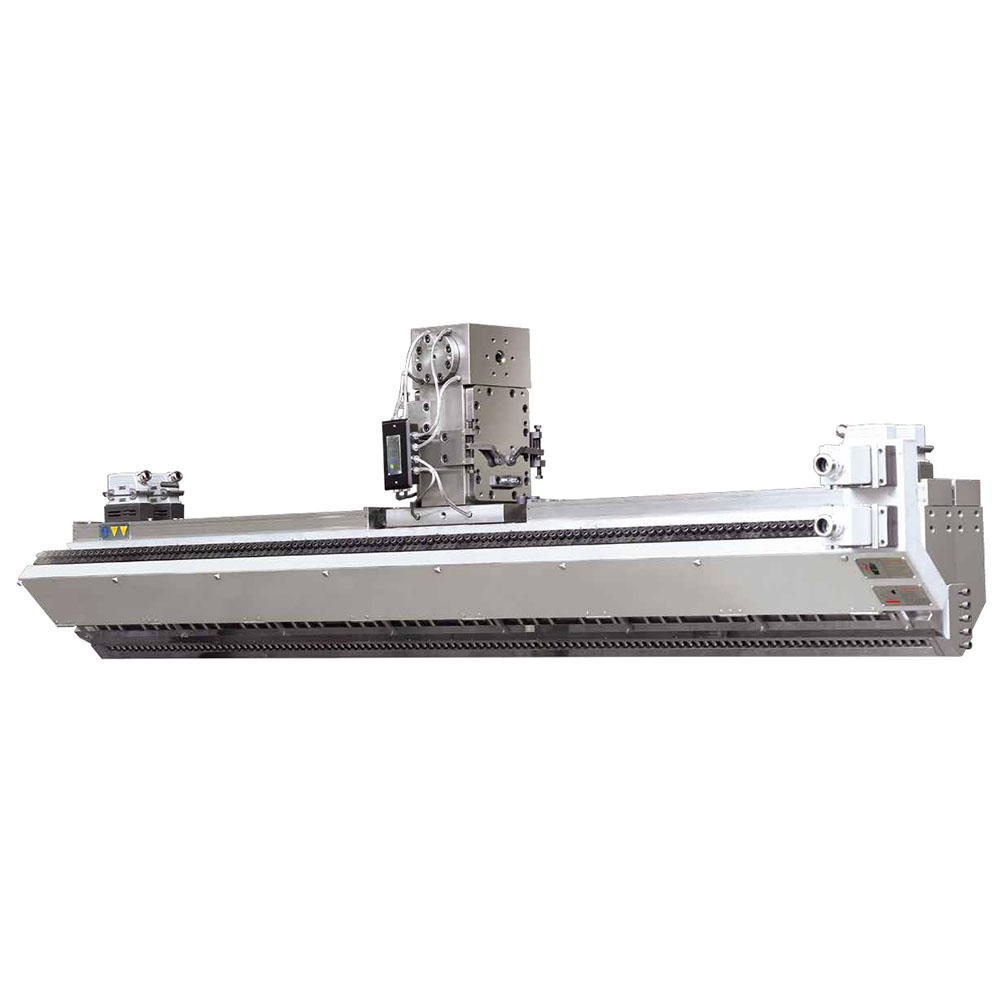

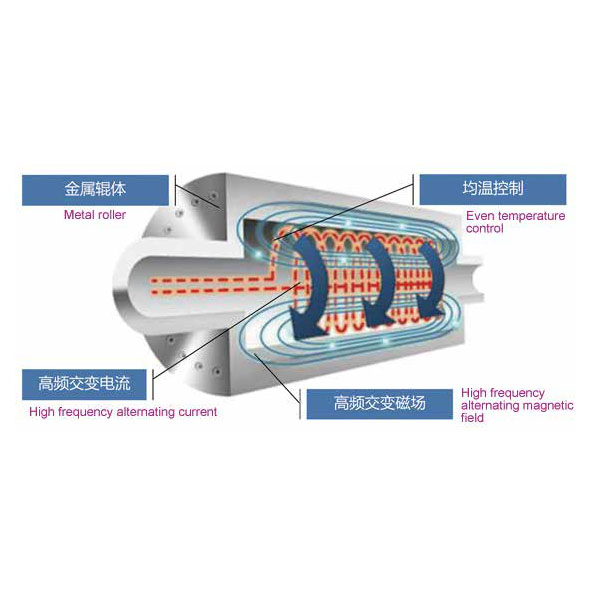

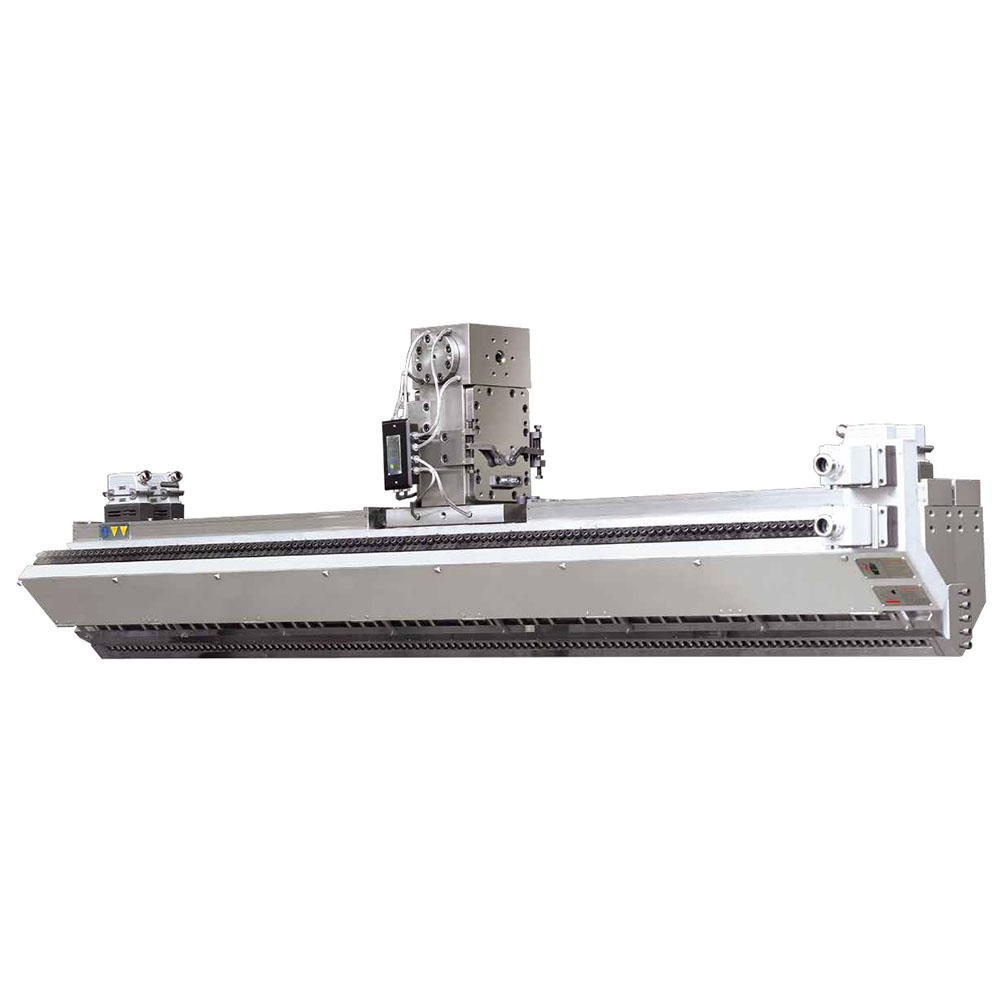

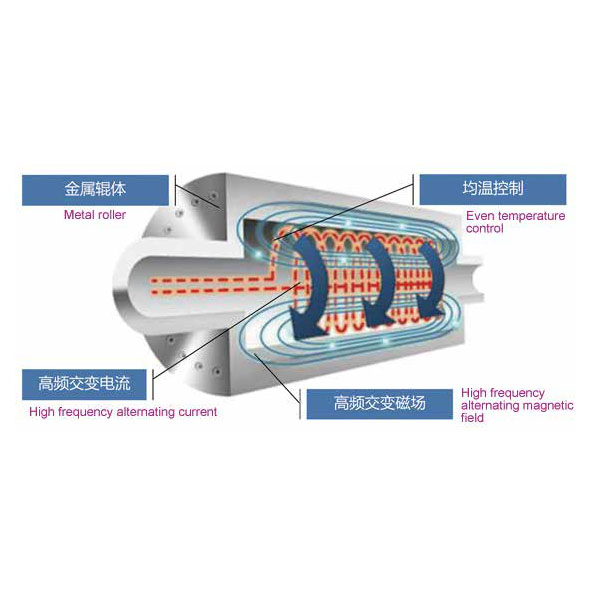

Electromagnetic Heating Roller

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Roller

Super Mirror Roller; Stretching Film Roller

Optical Film Roller; Casting Film Roller

Hot Mill Roller Embossing Roller; Vulcanize Roller Rubber Roller

Paper Making Roller; Coating Roller

Printing Roller; Nov-woven Roller

Carbon Fiber Roller; Electromagnetic Heating Roller

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Casting Film Roller

JWELL manufactured casting film roller strictly according to European professional manufacturing standards. Several steps of the welding and heat treatment process are applied to give insurance to the overall rigidity and reliability of the roller structure.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

T-Die Die head Mould

T-Die is used for extrusion production in order to provide custom engineered board line. Each T-die can meet customer requirements. Thickness and width adjustable.

Application

● Sheet production line (PP, PE, PMMA etc.).

● Plate, board production line (PVC, XPS, HIPS etc.).

● Cast film lines, coating & laminating line.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Micro-Structure Roller for Optical Film & Sheet

Microstructure roller makes the microstructure treat for the roller surface after the copperize, nickelage, to be the height class optics sheet or film which will be the key module parts of the LCD panel. The final product used in the LCD/LED display, mobile phone, 3D raster, prismatic lens, and microlens.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Thin-Wall Efficient Roller

For the thin-walled high-efficiency roller, the surface shell thickness is only 50%-70% of the standard roller; by reducing the area of the strikes, and enlarging the contact area with cooling water, the thermal conversion efficiency is increased. And to offset the roller rigidity, the overall circular runner design is adopted to increase the intensity of the roller. Under the same working condition, the thin wall high-efficiency roller boosted plate and sheet line output by 20% to 50%.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months -

Super Mirror Roller

Used for optical grade plates, sheets, and film products.

Super mirror surface roller is a key part of sheet and plate equipment. The rule is that the more smooth and precise the roller surface, the better the product quality.

And, JWELL machine always strikes for the smallest possible surface roughness tolerance to the level of Ra0.005um.

● Port: Shanghai, China

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW

● Terms of Payment: LC, T/T

● Certification: CE, ISO, UL, QS, GMP

● Warranty: 1 Year

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months