Manufacturer of Twin Screw Compounding Extruder - Screw&Barrel – JWELL

Manufacturer of Twin Screw Compounding Extruder - Screw&Barrel – JWELL Detail:

Product Description

FAQ

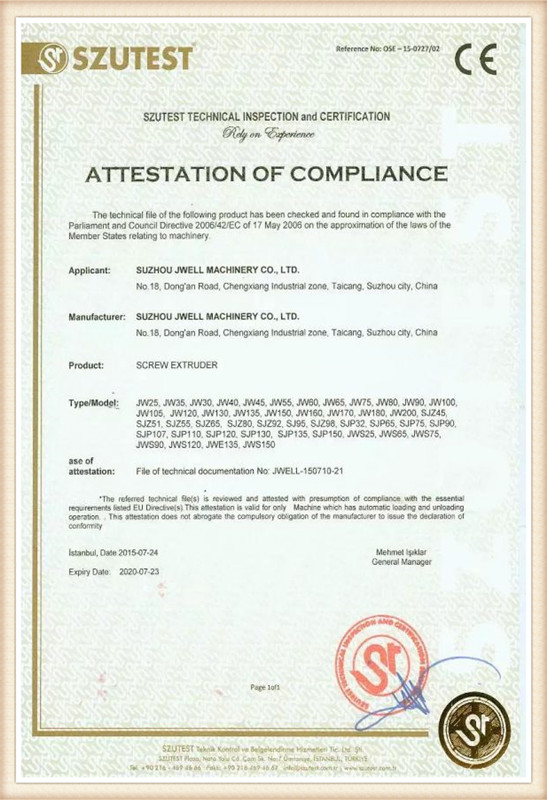

Our Certificates

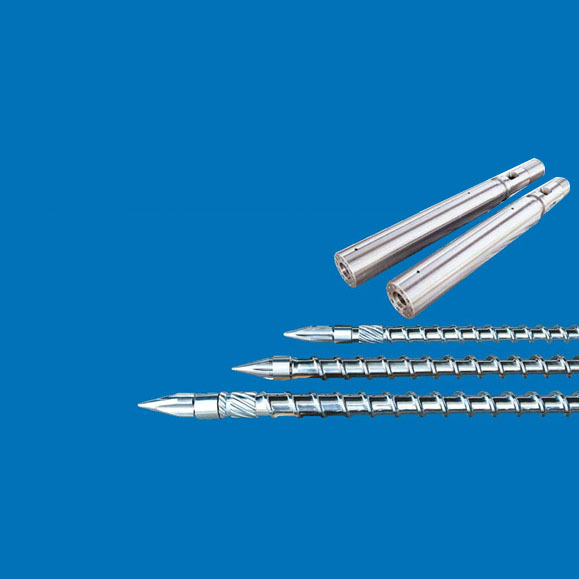

Screw And Barrel

Single screw and barrel

Material

Alloy –steel of High-quality

1) 38 CrMoA LA (JIS SACM645)

2) 42 CrMo(JIS SCM440)

3) 9 Cr18MoV

4) CW6Mo5Cr4V2

Heat-treatment

Nitriding treatment

Electroplated hard-chrome finish

Spray coating Bimetallic-alloy

Twin screw and barrel

Material

Alloy –steel of High-quality

1) 38 CrMoA LA (JIS SACM645)

2) 9 Cr18MoV

Heat-treatment

Nitriding treatment

Spray coating Bimetallic-alloy

| Technical data | |

| Depth of nitration layer | 0.50 -0.80mm |

| Hardness of nitration | 900-1000HV |

| Fragility of nitration | Less than grade 1 |

| Roughness of the surface | Ra0.4 |

| Linearity of the screw | 0.015mm |

| The surface hard chromium plating hardness after | |

| Nitrogenation | ≥ 950Hv |

| Chrome-plating layer thickness | 0.025 -0.085mm |

Screw And Barrel Technical Details

● Base material: 45# 40Cr

● Bimetallic type: Centrifugal casting

● Application: Injection molding machine & Extruder

● Products range: Inner diameter ?12- ?300mm

● Effective Length: 12000mm

● Nitrided layer thickness: 0.50-0.80mm

● Hardness: HV960

● Straightness: 0.015mm/m

● Chrome coated layer: 0.02-0.085mm

● Suitable plastic material: PP, PE, ABS, AS, PS etc.

● Material: ACM645, SCM440, 38CrMoAIA

Screw And Barrel Application

All kinds of SJZ and SJP extruders that our company designs especially for producing the PVC pipe and profile, our extruders can promise a good plasticization, high capacity and advanced electric control, and the electrical cabinet can be chosen by customer according to their own demands.leo.

For pipe Extrusion

| Extruder Model | Speed (RPM) | Motor (KW) | Capacity (kg/h) | Center Height (mm) | Weight (kg) | Dimension (M) |

|---|---|---|---|---|---|---|

| SJZ45/100 | 45 | 15/18.5 | 110 | 1050 | 3000 | 3.3*1.2*2.1 |

| SJZ50/105 | 45 | 18.5/22 | 125 | 1050 | 3000 | 3.6*1.1*2.1 |

| SJZ55/110 | 45 | 22/30 | 180 | 1050 | 3500 | 3.6*1.1*2.1 |

| SJZ65/132 | 45 | 37 | 380 | 1050 | 4000 | 4.2*1.5*2.4 |

| SJZ80/156 | 34.7 | 55 | 500 | 1050 | 5500 | 4.7*1.5*2.4 |

| SJZ80/173 | 37.6 | 75 | 680 | 1050 | 6000 | 3.9*1.6*2.5 |

| SJZ92/188 | 34.7 | 110 | 800 | 1100 | 8000 | 6*1.6*2.5 |

| SJZ110/220 | 34.7 | 160 | 1400 | 1100 | 9000 | 6.5*1.6*2.5 |

For Profile Extrusion

| Extruder Model | Speed (RPM) | Motor (KW) | Capacity (kg/h) | Center Height (mm) | Weight (kg) | Dimension (M) |

|---|---|---|---|---|---|---|

| SJZ45/100 | 34.7 | 15 | 60-80 | 1050 | 2500 | 3.3*1.2*2.1 |

| SJZ51/105 | 34.7 | 18.5 | 80-120 | 1050 | 3000 | 3.6*1.1*2.1 |

| SJZ55/110 | 34.7 | 22 | 100-150 | 1050 | 3500 | 3.6*1.1*2.1 |

| SJZ65/132 | 34.7 | 37/30 | 180-250 | 1050 | 4000 | 4.2*1.5*2.4 |

| SJZ80/156 | 34.7 | 55 | 300-400 | 1050 | 5500 | 4.7*1.5*2.4 |

| SJZ80/173 | 34.7 | 75 | 500-600 | 1050 | 6000 | 3.9*1.6*2.5 |

| SJZ92/188 | 34.7 | 110 | 600-800 | 1100 | 8000 | 6*1.6*2.5 |

| SJZ110/220 | 34.7 | 160 | 1200-1400 | 1100 | 10000 | 6.5*1.6*2.5 |

For production of PVC pipe

| Extrud Model | Speed (RPM) | Motor (KW) | L/D Ratio | Capacity (kg/h) | Center Height (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| SJP75/28 | 45 | 45 | 28:01:00 | 220-350 | 1050 | 4100 |

| SJP93/28/31 | 45 | 75 | 28:1/31:1 | 380-460 | 1050 | 4700 |

| SJP110/31 | 45 | 110 | 31:01:00 | 680 | 1050 | 6500 |

| SJP120/31/26 | 45 | 132 | 31:01:00 | 850 | 1050 | 7500 |

| SJP135/31 | 45 | 160 | 31:01:00 | 1100 | 1050 | 8400 |

For production of Profile

| Extrud Model | Speed (RPM) | Motor (KW) | L/D Ratio | Capacity (kg/h) | Center Height (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| SJP75/28 | 36 | 37 | 28:01:00 | 240 | 1050 | 4100 |

| SJP93/28/31 | 36 | 55 | 28:1/31:1 | 350 | 1050 | 4700 |

| SJP110/28 | 35.8 | 75 | 28:01:00 | 460 | 1050 | 6500 |

| SJP120/26 | 34.3 | 110 | 26:01:00 | 550 | 1050 | 7500 |

| SJP130/26 | 34.3 | 132 | 26:01:00 | 680 | 1050 | 8400 |

For production of PVC hard material and various cables palletizing

Please provide a valid CSV file.

Single Screw Extruder for HDPE Pipe

It is widely used in the area of water supply and gas supply. Feeding section is grooved structure with temperature controller, and easy to get high capacity and stable extrusion. With advanced BM screw structure, it is able to divide the HDPE material from solid to liquid.

High Efficient 38 Series

| Extruder Model | Screw Dia.(mm) | L/D Ratio | Motor (KW) | Capacity (kg/h) | Center Height (mm) |

|---|---|---|---|---|---|

| JWS60/40 | 60 | 40 | 90/110 | 360-450 | 1000 |

| JWS75/38 | 75 | 38 | 132/160 | 400-650 | 1000 |

| JWS90/38 | 90 | 38 | 250/280 | 800-1000 | 1150 |

| JWS120/38 | 120 | 38 | 315/355 | 900-1200 | 1300 |

Classic 33 Series

| Extruder Model | Screw Dia.(mm) | L/D Ratio | Motor (KW) | Capacity (kg/h) | Center Height (mm) |

|---|---|---|---|---|---|

| JWS45/33 | 45 | 33 | 18.5/22/30 | 60-100 | 1000 |

| JWS65/33 | 65 | 33 | 45/75/90 | 100-250 | 1000 |

| JWS75/33 | 75 | 33 | 110/132 | 250-350 | 1000 |

| JWS90/33 | 90 | 33 | 160/185 | 450-550 | 1150 |

| JWS120/33 | 120 | 33 | 280/315 | 700-900 | 1300 |

| JWS150/33 | 150 | 33 | 355/400 | 1000-1300 | 1300 |

Features:

By using the new type barrier screw design, this extruder has a high extrusion capacity in high RPM with the low energy consumption, and this extruder can gain a good mixing effect in the low temperature, and this extruder can control the material shearing to get the ideal and even melt temperature, so that the ripple mark in the inner wall of the big diameter pipe can be avoided.

Single Screw Extruder for HDPE Pipe

This model of equipment mainly used to extrude profile, the structure and form of screws and barrels vary a lot, and the screws and barrels are processed precisily which can gurantee a good plasticization, high capacity and can meet different customer’s needs, the electrical controling parts are equiped in high class which made it safe to operate. Suitable for PVCPCABS Profile.

| Extruder Model | Screw Dia.(mm) | L/D Ratio | Motor (KW) | Capacity (kg/h) | Center Height (mm) | Polymer Processing |

|---|---|---|---|---|---|---|

| JWS45 | 45 | 25/28 | 11/15/18.5 | 10-100 | 1000 | PC/ABS/PC |

| JWS65 | 65 | 25/28 | 18.5/22/30 | 10-100 | 1000 | PVC/PC/ABS |

| JWS75 | 75 | 25/28 | 37 | 10-100 | 1000 | PVC/PC/ABS |

| JWS80 | 80 | 28/30 | 37 | 10-90 | 1000 | PP/ABS/PC |

| JWS90 | 28 | 28/30 | 45 | 10-90 | 1000 | PP/ABS/PS |

| JWS120 | 120 | 28/30 | 75 | 10-90 | 1000 | PC/ABS |

PVC PVG Conveyer Belt Cover Extruder

In order to the customer’s technics requirement for the conveter belt, Jwell successfully develops serials conveyer belt cover extruder and relation mould, it can be molding for the pvc belt’s surface, adjust the thickness of the cover, leave out the others. This extruder install on the left and right,have good plastic, high output, low power and the high design for the produce method.

| Extruder Model | Screw Dia.(mm) | L/D Ratio | Speed (RPM) | Capacity (kg/h) | Center Height (mm) | Weight (T) | Dimension (MM) |

|---|---|---|---|---|---|---|---|

| JWS90/30 | 90 | 30 | 10-45 | 150 | 1200 | 4 | 3650*2520*2100 |

| JWS120/28 | 120 | 28 | 10-45 | 300 | 1200 | 5 | 4500*2520*2200 |

| JWS150/28 | 150 | 28 | 10-45 | 400 | 1200 | 6.5 | 5500*2520*2300 |

PS PC Electronic Narrow Band Extruder

PS/PC narrow band is a king of packaging products, mainly for the IC, resistance, inductance, capacitance, connectors, fuses,switches and other electronice components of the packaging. This product is currently PS and PC for three layers of composite extrusion.

Please provide a valid CSV file.

All kinds of co-extrusion machine

n order to meet the actual needs of various customers, the company can provide all kinds of uses co-extrusion machine, used for profile pre and after Co-extrusion, or wood plastic products surface coating, mark line for pipes according to customers[ special requirements, special design custom-made.

For Pipe Mark Line

| Extruder Model | Screw Dia.(mm) | L/D Ratio | Speed (RPM) | Motor (KW) | Barrel Heating(KW) | Capacity (kg/h) | Center Height (mm) |

|---|---|---|---|---|---|---|---|

| JWS25/25A | 25 | 25 | 1–15 | 0.75 | 3 | 3 | 1100±50 |

| JWS25/25B | 25 | 25 | 1-50 | 1.5 | 3 | 8 | 1100±50 |

| JWS30/28 | 30 | 28 | 1-50 | 3 | 3.6 | 10 | 1100±100 |

For Profile Co-Extrusion

| Extruder Model | Screw Dia.(mm) | L/D Ratio | Speed (RPM) | Motor (KW) | Barrel Heating(KW) | Capacity (kg/h) | Center Height (mm) |

|---|---|---|---|---|---|---|---|

| JWS30/25 | 30 | 25 | 1-60 | 3–4 | 3 | 8–10 | 800-1200 adjustable |

| JWS35/25 | 35 | 25 | 1-50 | 4–5.5 | 6.9 | 10–12 | 800-1200 adjustable |

| JWS45/25 | 45 | 25 | 1-58 | 5.5–7.5 | 9 | 20–25 | 1100±100 |

| JWS50/25 | 50 | 25/28 | 1-58 | 11–15 | 10 | 25–35 | 1100±100 |

| JWS65/25 | 65 | 25/28 | 1-80 | 15–22 | 12 | 35–40 | 1100±100 |

| SJZ35/75 | 35/75 | 22.97 | 1-39 | 11 | 9 | 35–40 | Adjustable |

Spinning Extruder

JWM series extruders are used for melt spining of PET, PA6, PA66, PP chips.

The LTM designed in screw, and the melt quality is better. The precision of screw and barrel is higher after professional proce ssing. And equiped high precision bevel-teeth gear box, operating stability, lowest noise.

Assemble strong push bearing in ord to guarantee bearing huge axle power and be able to select to equip imported high speed bearing and seal parts.

| Extruder Model | Speed (RPM) | L/D Ratio | Capacity (kg/h) | Pressure Mpa | Transmission Power kw | Heating Power kw | Heating Zone | Heating Voltage | Center Height mm | Weight (T) |

|---|---|---|---|---|---|---|---|---|---|---|

| JWM45/25 | 20-90 | 25 | 38 | 15–25 | 7.5 | 8 | 3 | 220 | 340 | 1 |

| JWM65/25 | 20-90 | 25 | 78 | 15–25 | 18.5 | 16 | 5 | 220 | 340 | 1.3 |

| JWM80/25 | 20-80 | 25 | 115 | 15–25 | 37 | 27 | 5 | 220 | 510 | 1.8 |

| JWM90/25 | 20-80 | 25 | 196 | 15–25 | 45 | 32 | 5 | 220 | 510 | 2 |

| JWM105/25 | 20-70 | 25 | 295 | 15–25 | 55 | 45 | 5 | 220 | 610 | 3 |

| JWM120/25 | 20-60 | 25 | 390 | 15–25 | 75 | 54 | 6 | 220 | 660 | 3.5 |

| JWM135/25 | 20-60 | 25 | 535 | 15–25 | 90 | 63 | 6 | 220 | 660 | 4.2 |

| JWM150/25 | 20-60 | 25 | 652 | 15–25 | 110 | 76.5 | 6 | 380 | 710 | 5 |

| JWM160/25 | 20-60 | 25 | 705 | 15–25 | 132 | 85.5 | 6 | 380 | 710 | 6 |

| JWM170/25 | 20-60 | 25 | 850 | 15–25 | 160 | 103.5 | 6 | 380 | 720 | 8 |

| JWM180/25 | 20-60 | 25 | 972 | 15–25 | 185 | 110 | 7 | 380 | 800 | 10 |

| JWM200/25 | 20-60 | 25 | 1050 | 15–25 | 200 | 150 | 7 | 380 | 1000 | 12 |

PP Non-woven Fabrics Extruder

JWM series Non-woven fabrics Extruder are specialized in PP Non-woven fabrics production. Normally it uses two extruders in series. the screw L/D of the main extruder is 30: 1 the ancillary extruder mainly used for machining leftover material and flot- sam drapery which can be recycled on the line, the L/D is mainly 15:1. various kinds of the extruder model for different width Non-woven fabrics products.

| Extruder Model | L/D Ratio | Speed (RPM) | Transmission Power kw | Heating Power kw | Heating Zone | Heating Voltage | Center Height mm | Weight (T) | Note |

|---|---|---|---|---|---|---|---|---|---|

| JWM135/30 | 30 | 20–60 | 75 | 80 | 6 | 220 | 660 | 4.5 | suitable for 1.6m |

| JWM105/15 | 15 | 20–80 | 15/18.5 | 18 | 4 | 220 | 660 | 2 | suitable for 1.6m |

| JWM150/30 | 30 | 20–60 | 110 | 90 | 7 | 380 | 710 | 5.5 | suitable for 2.4m |

| JWM105/15 | 15 | 20–80 | 15/18.5 | 18 | 4 | 220 | 710 | 2 | suitable for 2.4m |

| JWM160/30 | 30 | 20–60 | 132 | 100 | 7 | 380 | 710 | 6.5 | suitable for 2.4m |

| JWM105/15 | 15 | 20–80 | 22 | 18 | 4 | 220 | 710 | 2 | suitable for 2.4m |

| JWM170/30 | 30 | 20–60 | 132 | 110 | 7 | 380 | 710 | 8.5 | suitable for 3.2m |

| JWM105/15 | 15 | 20–80 | 22 | 18 | 4 | 220 | 710 | 2 | suitable for 3.2m |

| JWM180/30 | 30 | 20–50 | 160 | 120 | 7 | 380 | 720 | 10.5 | suitable for 3.2m |

| JWM120/15 | 15 | 20–80 | 30 | 24 | 4 | 220 | 720 | 2.5 | suitable for 3.2m |

JWS45/25 single Screw Extruder for Ultra High Molecular Weight Polyethylene (UHMW-PE)

The extruder has our patented design for screw and barrel, which can be used to process more than 1.5 million molecular of the powder material. By overcoming poor flow ability, Mechanical Properties decreasing due to easy degaradation, etc. The extruder can have stable output and reliable plasticization during production. Also the extruder equips high efficient and energy saving driving motor, infrared energy-saving heaters, reducing energy comsumption.

The extruder has a compact structure, beautiful appearance, small space, easy operation etc, can be used to produce a variety of small plates, profiles, rods production.

| Model No. | JWS45/25 |

| Screw RPM | 3–25 |

| Capacity(kg/h) | 3–10 |

| Motor Power(kw) | 5.5 |

| Heating Power( kw) | 9.4 |

Screw And Barrel Machining Process

FAQ

Trade Capacity

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Is Jwell Machinery a Manufacturer?

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

How do you ensure your machinery and service quality?

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

How long is the delivery date?

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

How can I order and make payments?

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

What is your Minimum Order Quantity?

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

What is your production capacity?

We produce more than 2000 advanced extrusion lines every year world wide.

What about shipping?

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Is there any pre-after sale service?

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for Manufacturer of Twin Screw Compounding Extruder - Screw&Barrel – JWELL , The product will supply to all over the world, such as: Jordan, Spain, Ottawa, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!