Manufacturing Companies for GPPS Sheet extrusion line - 1600mm width PP Meltblown Non-woven Fabric Production Line – JWELL

Manufacturing Companies for GPPS Sheet extrusion line - 1600mm width PP Meltblown Non-woven Fabric Production Line – JWELL Detail:

Product Description

FAQ

Our Certificates

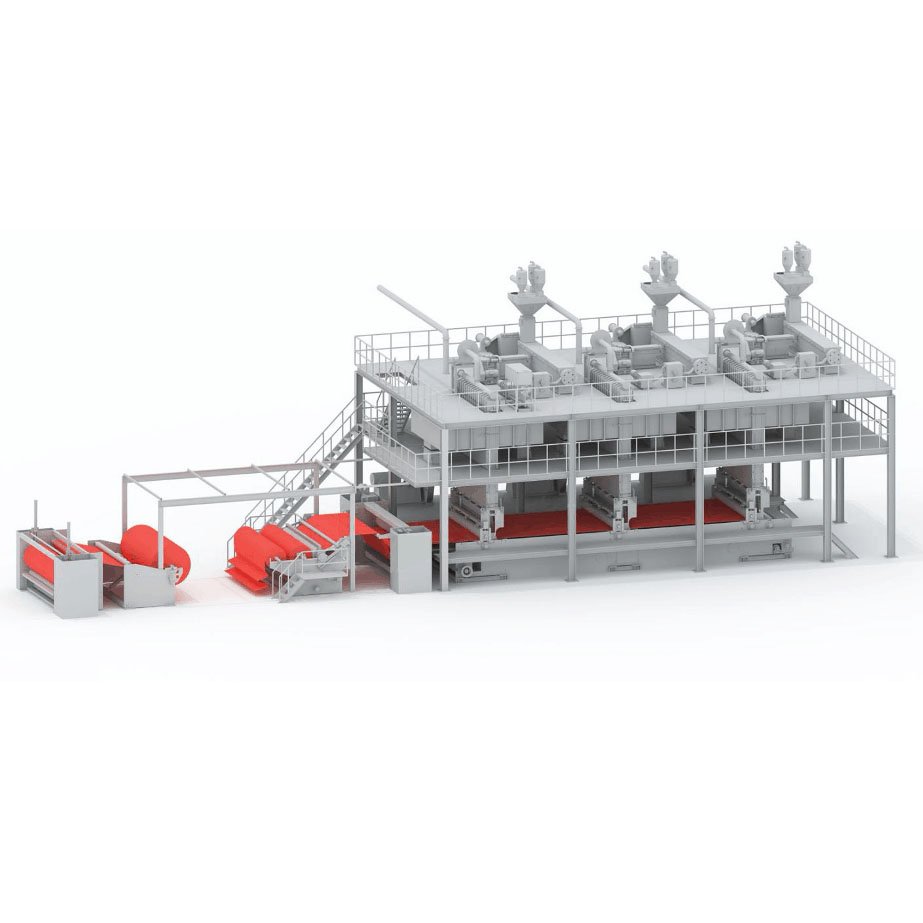

PP Melt-Blown Nonwoven Fabric Production Line Overview

The PP Melt-blown Nonwoven Fabric Production line uses polypropylene melt-blown raw materials as the main raw material, supplemented with additives such as electrostatic auxiliary masterbatch and color masterbatch, to produce polypropylene melt-blown nonwoven fabrics with different colors, different properties and suitable for different uses.

| Conditions of usage | 380V/3P/50Hz |

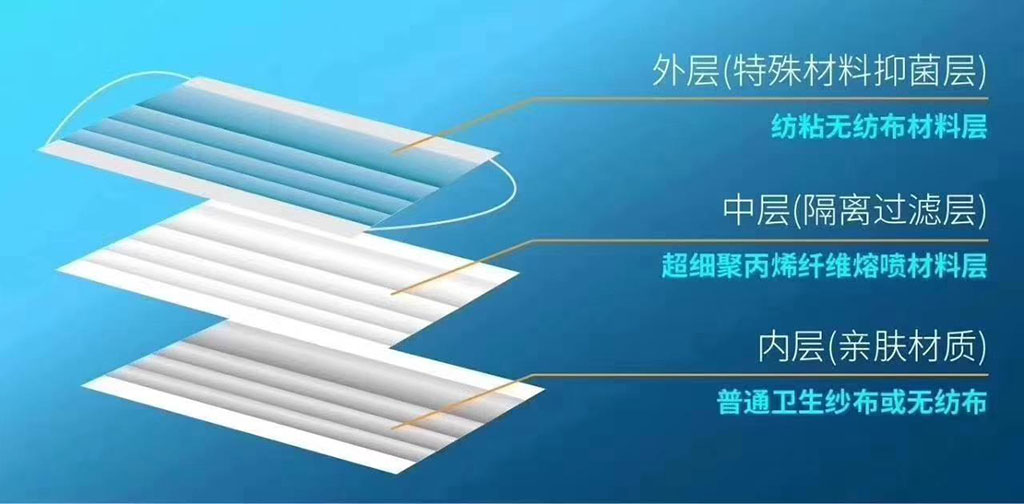

| Products application | Melt Blown Filtration Material, Facial Mask Filtration Materials |

| Raw Material | PP chips (special materials for melt-blown) MFI=1200~1800 g/min Recommended 1500g/min |

| Product width | Width: 1600mm |

| Product gram weight range | 25-80g/ m2 |

| Extrusion capacity | 1–1.5 tons/24 hours, as the product gram weight changes, the production line capacity changes accordingly |

| Max. mechanical speed | 0-50m/min |

| Fiber fineness | 2-5μm |

| Installed power | About 560KW |

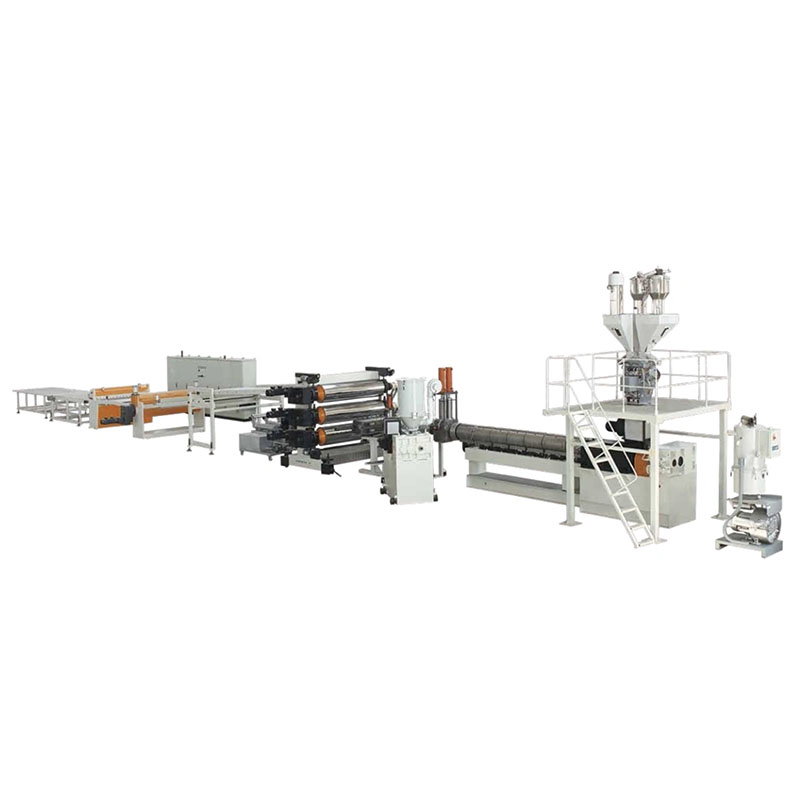

PP Meltblown Non-Woven Fabric Production Line

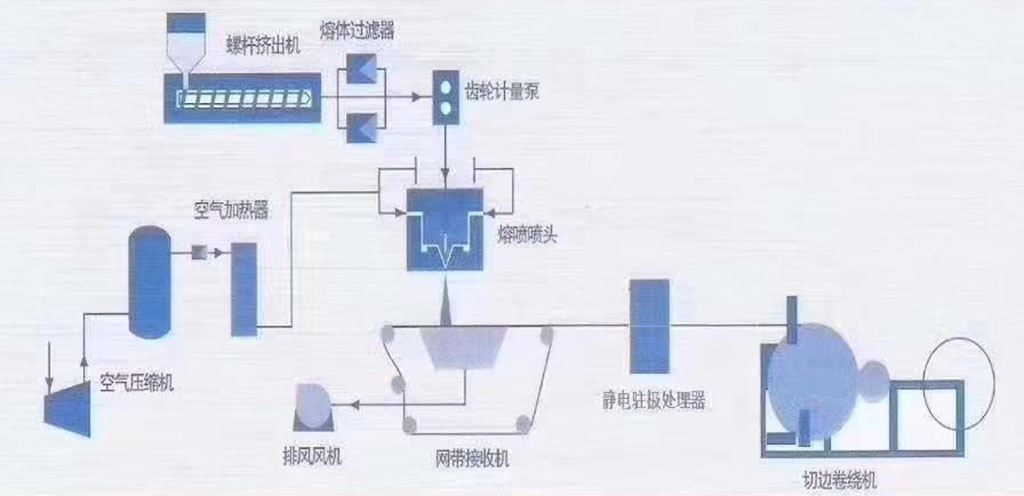

PP Meltblown Nonwoven Fabric Production Line includes raw material input, raw material dryer, extruder, screen changer, metering pump, die (single, composite), distribution plate, spinneret, netting device, winding device Wait.

The actual production process of melt-blown cloth is relatively complicated, involving many disciplines such as polymer science, fluid mechanics, airflow, spinning science, etc., and the requirements for equipment manufacturing are also high. The key is the complete set of production equipment for melt-blown cloth.

PP Meltblown Nonwoven Fabric Production Line Core Component

Die System

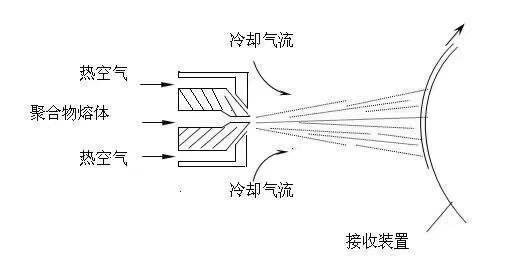

The die system of the melt-blown die assembly is composed of a bottom plate, a spinneret, an air plate, and a heating element. The uniformity of melt-blown products is closely related to the die head, but the processing accuracy of the melt-blown die head is very high, and the manufacturing cost of the die head is expensive.

Spinneret

The spinneret is the extrusion die for the production of melt-blown cloth.

The spinneret mold is a precision mold. The thickness of the melt-blown cloth depends on the spinneret. The precision of the mold cannot be reached, and the sprayed wire is too thick to achieve the barrier effect.

Spinneret Nozzle

The production of spinneret nozzles is difficult. This kind of nozzle is small in size, and it is necessary to process a complex hole on the small nozzle, which is extremely difficult to process and takes a long time to process.

If the processing accuracy is not high, it is easy to cause blockage or affect the melt-blown flow rate and form crystallization, and the final melt-blown cloth produced will not meet the requirements.

Melt Blown Air Heater

The air heater is one of the main equipment in the melt-blown production process because a large amount of high temperature and clean air is required in the melt-blown process.

The air heater heats the air delivered by the Roots blower or air compressor to a specified temperature and then delivers it to the melt-blown die. It is not enough to rely on the small holes of the spinneret, and it needs to be stretched by the wind.

The air heater is a pressure vessel, and at the same time it must resist the oxidation of high-temperature air, so the material must be stainless steel.

When selecting a heater for PP Meltblown Nonwoven Fabric Production Line, you should pay attention to the following aspects:

1. The air needs to be clean during the processing. First, the air source input to the air heater should be clean and dry, and the material of the part in contact with the air in the heater must be at least SUS304 grade;

2. Because the air source in the normal process is provided by an air compressor or a Roots blower, the air heater should be a ducted heater with pressure bearing capacity;

3. The heater selection should consider in detail factors such as air volume, temperature difference, and heat loss during pipeline transportation;

4. The melt-blown process requires higher temperature control accuracy of the air heater. In terms of temperature control, a module with higher temperature control accuracy should be selected, and the specific surface temperature difference is large, which affects the stability of the air temperature.

Melt Metering Pump

The melt metering pump is a positive displacement conveying device, and the flow rate is strictly proportional to the speed of the pump.

The melt metering pump is used for precise metering, controlling the output and the fineness of the fiber, and continuously and uniformly transporting the melt to the spinneret. Melt blown cloth metering pump has the advantages of stable output pressure, improving product quality, increasing extrusion output, and reducing unit energy consumption.

Screen Changer

The main function of the special screen changer for melt-blown cloth is to filter out the impurities in the melt, so as not to block the spinneret holes.

The special screen changer for melt-blown cloth is composed of the main body, a sealing component, a porous plate, a filter screen, and a switching device. The main body of the melt-blown cloth screen changer is made of special alloy materials through strict forging, surface heat treatment, and precise metal processing.

The machine requirement of melt-blown material is to change the screen continuously. Generally, a double-station screen changer is used, and different screws are matched with metering pumps of different specifications.

Electret Equipment

Electret equipment is to increases filtration efficiency and reduces filtration resistance. The equipment consists of three parts, the generator host, the step-up transformer, and the electret processing frame.

PP Melt-blown Nonwoven Fabric Production line Main Technical Advantages

1. The hot-rolling machine selects and uses high-quality alloy steel.

2. The steel structure of the wall goes through heat treatment and careful treatment.

3. Linear speed is adjustable isochronously.

4. Independent oil-heating system.

5. Calendar drive style: one motor with one roller or one motor with two rollers.

6. Crossing of roller central line can be adjusted both manually and electrically increasing calendar radian.

7. Calendar max line pressure:150kg/cm2.

8. The latest hydraulic pressure stretch bending technique compensates central height.

9. Roller bearing, equip lubrication cooling station.

Main technical parameters

| Screw diameter (mm) | Specification model (L/D) | Screw speed (rpm) | Transmission power (Kw) | Heating power (Kw) | Heating zone | Heating voltage (V) | Center height (mm) | Weight (t) |

| ø135 | 135/30 | 20-60 | 75 | 80 | 6 | 220 | 660 | 4.5 |

| ø105 | 105/15 | 20-80 | 15/18.5 | 18 | 4 | 2 | ||

| ø150 | 150/30 | 20-60 | 110 | 90 | 7 | 380 | 710 | 5.5 |

| ø105 | 105/15 | 20-80 | 15/18.5 | 18 | 4 | 220 | 2 | |

| ø160 | 150/30 | 20-60 | 132 | 100 | 7 | 380 | 710 | 6.5 |

| ø105 | 105/15 | 20-80 | 22 | 18 | 4 | 220 | 2 | |

| ø170 | 170/30 | 20-60 | 132 | 110 | 7 | 380 | 710 | 8.5 |

| ø105 | 105/15 | 20-80 | 22 | 18 | 4 | 220 | 2 | |

| ø180 | 180/30 | 20-50 | 160 | 120 | 7 | 380 | 720 | 10.5 |

| ø120 | 120/15 | 20-80 | 30 | 24 | 4 | 220 | 2 |

Equipment List

| Automatic Dosing & Feeding Unit | 1 unit |

| Screw Extruder | 1 unit |

| Screen Changer | 1 unit |

| Metering Pump | 1 unit |

| Melt Distribution Pipes | 1 unit |

| Die Assembly | 1 unit |

| Heated Air System | 1 unit |

| Air Heat | 1 unit |

| Exhaust/Suction Fan Blower | 1 unit |

| Connecting Air Duct | 1 unit |

| Web-forming Collector | 1 unit |

| Electret Processing Equipment | 2 unit |

| Winder | 1 unit |

| Electric Control System | 1 unit |

| Spare parts | Several |

Spare Part

| Extruder Heating Ring | 1piece |

| Thermal Couple | 5 pieces |

| Screw Dismantling Tools | 1 set |

| Solenoid Valve | 2 pieces |

| Contactor | 2 pieces |

| Relay | 2 pieces |

| Air Switch | 2 pieces |

| Screen changer Heating rod | 6 pieces |

| Metering heating rod | 4 pieces |

| Knifes | 10 pieces |

PP Meltblown Non-Woven Fabric Production Lineapplications

non woven fabric making machine

Video

FAQ

Trade Capacity

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Is Jwell Machinery a Manufacturer?

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

How do you ensure your machinery and service quality?

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

How long is the delivery date?

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

How can I order and make payments?

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

What is your Minimum Order Quantity?

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

What is your production capacity?

We produce more than 2000 advanced extrusion lines every year world wide.

What about shipping?

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Is there any pre-after sale service?

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for Manufacturing Companies for GPPS Sheet extrusion line - 1600mm width PP Meltblown Non-woven Fabric Production Line – JWELL , The product will supply to all over the world, such as: Uruguay, Iran, Milan, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.